Choke Manifold / Kill Manifold

- Reduced weight and footprint to allow for standard freight options.

- Meet 6A, 16C, NACE MR-0175.

- Offers manual and/or hydraulic actuator options.

- Universal function LCP tested and delivered with manifold.

- Can fit with fixed base or lifting base.

- Hydraulically actuated components allow for remote operation.

- Technical Specification

- More Details

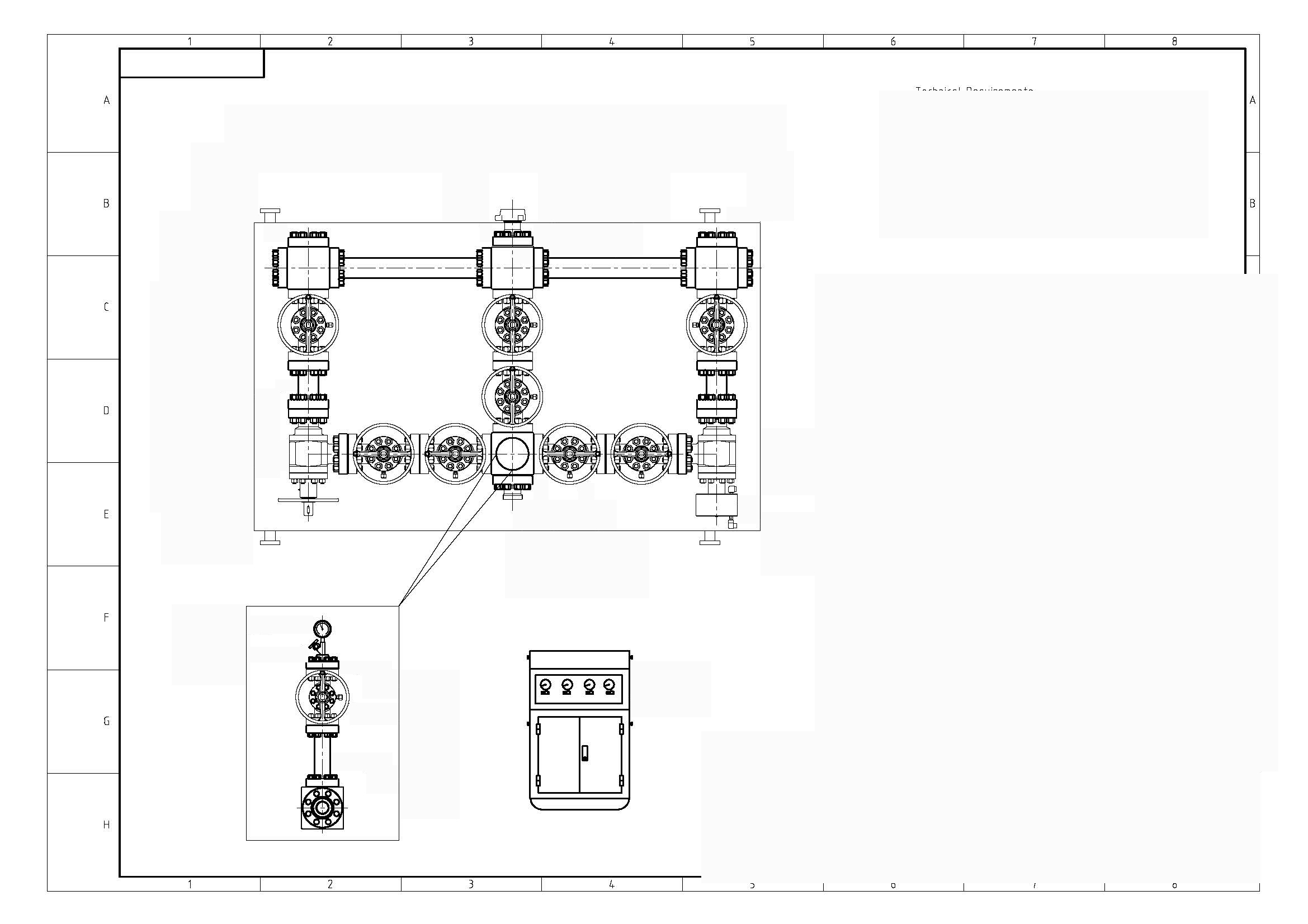

- Drawing

- Contact Us

| Item Name | Choke Manifold | |||

| Model | JG-35 | JG-35 | JG-70 | JG-105 |

| Main path and Side path in(mm) | 3 1/8×2 1/16(80×52) 4 1/16×2 9/16(103×65) 4 1/16×3 1/16(103×78) | |||

| Working Pressure psi (mpa) | 3000(21) 5000(35) |

3000(21) 10000(70) |

||

| Working Temperature ℃ (°F) | P.U -29~121 (-20~250) | |||

| Working medium | Mud Gas(sulfur-hydrogen) | |||

| Material grade | DD-FF | |||

| Item Name | Kill Manifold | ||

| Model | YG-35 | YG-70 | YG-105 |

| Main path and Side path in(mm) | 3 1/8×2 1/16(80×52) 4 1/16×2 9/16(103×65) 4 1/16×3 1/16(103×78) | ||

| Working Pressure psi(mpa) | 5000(35) | 10000(70) | 15000(105) |

| Working Temperature°C(°F) | P.U -29~121 (-20~250) | ||

| Working medium | Mud Gas(sulfur-hydrogen) | ||

| Material grade | DD-FF | ||

The choke and kill manifold is a necessary device for successful control on well kick and implementation of oil and gas well pressure control technologies. It is designed, manufactured and inspected in accordance with 16C.

Choke manifold consists of choke valves, gate valves, line pipes, fittings, pressure gauges and other components. It is adopted to execute new drilling-well’s technique of balance pressure, which can avoid pollution of oil-layer, improve the speed of drilling and control blowout effectively. One end of the device connects with the side flange of BOP spool. When BOP closes, it can control the finite pressure from casing by adjusting the choke valve’s opening, so balanced drilling can work under minimum pressure-difference.

Kill manifold consists of check valves, gate valves, line pipes, pressure gauges. In case of increase in well head pressure, the kill manifold can provide a means of pumping heavy drilling fluid into the well to balance bottom hole pressure so that well kick and blowout can be prevented. In this case, by using blow down lines connected to the kill manifold, the increasing well head pressure also can be released directly for bottom hole pressure release. or water and extinguishing agent can be injected into the well by means of kill manifold.

Learn More When Inquiring

Buyer’s Guide

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

We can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us your money will be safe.

Get Quick Response

Lake Petro is located in Dongying City, which is famous for Shengli Oilfield and the largest manufacturing hub of petroleum equipment in China. Following the principle of “quality first, science and technology innovated, people oriented”, every Lake Petro person is sparing no effort to provide the customers with best products and services. Our products are based on advanced production line and testing equipment, our products are designed and manufactured according to certification of ISO, GOST, etc.