Fiber Reinforced Plastic Pipe

- High corrosion resistance.

- Light weight to make operation and transportation easy.

- With longed service life and higher cost performance than steel material.

- No easy scaling or waxing.

- Technical Specification

- More Details

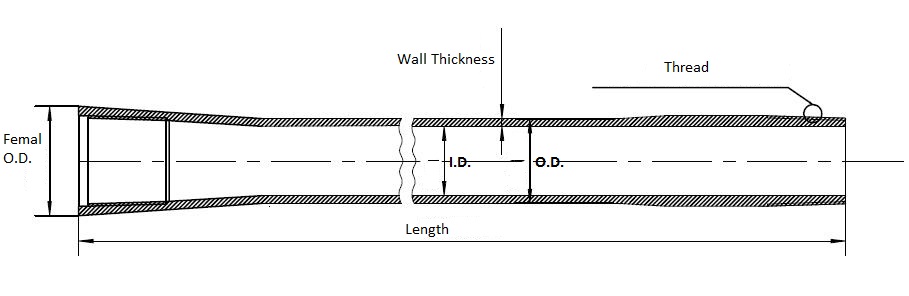

- Drawing

- Contact Us

| HIGH-PRESSURE GRE LINE PIPE & FITTINGS | |

| Diameter | DN40 ~ DN900 |

| Pressure rating | 3.45MPa ~ 34.5MPa |

| Product Standards | 15HR-2016 High Pressure Glass Fiber Piping Specification

SY/T 6267-2006 High Pressure Glass Fiber Pipe Code |

| Connection Type | Thread Connection, Flange end, Coupling End, etc. |

| Thread Connection | According to 5B |

| Medium Temperature | ≤ 65.5℃ for Acid anhydride GRE

≤ 93.3℃ for Amine epoxy GRE |

| Applications | Oil, gas, water mixture transport in petroleum, petrochemical and other areas |

| LOW-PRESSURE GRP LINE PIPE & FITTINGS | |

| Diameter | DN50 ~ DN2000 |

| Pressure rating | 0 ~ 6.9MPa

Can be designed and produced according to customer’s demands. |

| Product Standards | 15LR-2001 Specification for Low Pressure Fiberglass Line Pipe and Fittings

SY/T 6266-2004 Low Pressure Fiberglass Line Pipe and Fittings JC/T 552-2011 Filament-wound Thermosetting Resin Pressured Pipe |

| Connection Type | Socket (locking) joint, flat butt joint |

| Applications | Oil field, chemical industry, municipal, water conservancy, etc. |

Fiber reinforced plastic pipe (FRP Pipe), also known as fiber-reinforced polymer, is a composite material made of a polymer matrix reinforced with fibers.

The fibers we commonly use is glass, including GFRP (Glass Fiber Reinforced Polymer) & GFRE (Glass Fiber Reinforced Epoxy). The material type includes amine and anhydride.

FRP materials have been widely used in many industries, like oil & gas well drilling, water well drilling, geothermal well, hot spring, petrochemical pipeline, refining and chemical, etc. Both downhole and ground application can be met with.

For downhole application, GRE material can be made to tubing, casing, screen pipe, etc.

FRP Fittings include: flanges, couplings, elbow, tanks, etc.

Learn More When Inquiring

Buyer’s Guide

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

We can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us your money will be safe.

Get Quick Response

Lake Petro is located in Dongying City, which is famous for Shengli Oilfield and the largest manufacturing hub of petroleum equipment in China. Following the principle of “quality first, science and technology innovated, people oriented”, every Lake Petro person is sparing no effort to provide the customers with best products and services. Our products are based on advanced production line and testing equipment, our products are designed and manufactured according to certification of ISO, GOST, etc.