Square Kelly / Hexagonal Kelly

- Our kellys have been exported to Turkey, Hungary, Singapore and Middle East etc.

- Kellys are manufactured according to API-7-1 Spec.

- The kellys are made of AISI 4142H-4145H forged or rolled alloy structural steel.

- Technical Specification

- More Details

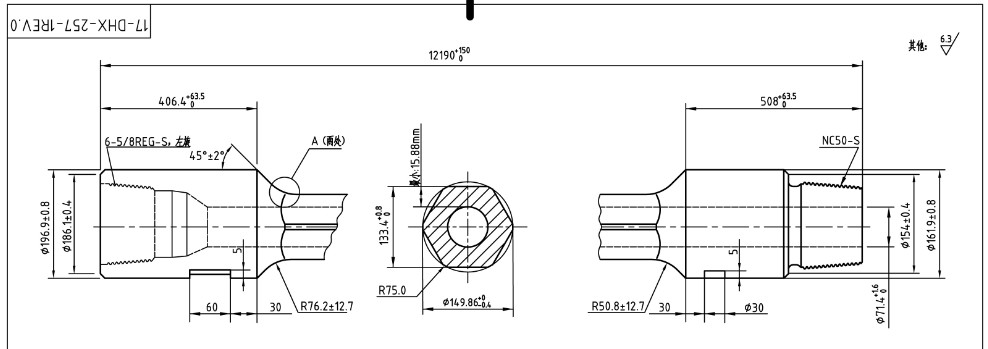

- Drawing

- Contact Us

| Nom. Size (in) |

Top Connection(LH) | Bottom Connection | I.D. (in) | Drive Section

(in) |

||||

| Standard

O.D.(in) |

Optional

O.D.(in) |

Square

O.D.(in) |

Hex.

O.D.(in) |

Square | Hex. | A | B | |

| 2-1/2 | 6-5/8REG 7-3/4 | 4-1/2REG 5-3/4 | NC26 | 1-1/4 | 3-2/7 | |||

| 3 | 6-5/8REG 7-3/4 | 4-1/2REG 5-3/4 | NC31 4-1/8 | NC26 3-3/8 | 1-3/4 | 1-1/4 | 4 | 3-3/8 |

| 3-1/2 | 6-5/8REG 7-3/4 | 4-1/2REG 5-3/4 | NC38 4-3/4 | NC31 4-1/8 | 2-1/4 | 1-3/4 | 4-1/2 | 4 |

| 4-1/4 | 6-5/8REG 7-3/4 | 4-1/2REG 5-3/4 | NC46 6-1/4 | NC38 4-3/4 | 2-4/5 | 2-1/4 | 5-4/7 | 4-4/5 |

| 6-5/8REG 7-3/4 | 4-1/2REG 5-3/4 | NC50 6-3/8 | NC38 4-3/4 | 2-4/5 | 2-1/4 | 5-4/7 | 4-4/5 | |

| 5-1/4 | 6-5/8REG 7-3/4 | 5-1/2FH 7 | NC46 6-1/4 | 3-1/4 | 3 | 7 | 6 | |

| 6-5/8REG 7-3/4 | NC56 7 | NC50 6-3/8 | 3-1/4 | 3-1/4 | 7 | 6 | ||

| 6 | 6-5/8REG 7-3/4 | 5-1/2FH 7 | 3-1/2 | 6-4/5 | ||||

| 6-5/8REG 7-3/4 | NC56 7 | 3-1/2 | 6-4/5 | |||||

Kellys are manufactured with one of two drive configurations, square or hexagonal. Square kellys are furnished as forged or machined in the drive section. Hexagonal or fully machined square kellys are machined from full length quenched and tempered round bars.

Square Kelly and hexagonal kellys are fabricated as per requirements of customers. The kellys are made of AISI 4142H-4145H forged or rolled alloy structural steel. Quenching plus tempering thermal treatment will be conducted over the whole length. Its Brinell hardness can reach 285-341 on the basis of such thermal treatment. Charpy impact energy: >or =54J. The formulated process can ensure that the misalignment of the hole reaches the standard wall thickness. Kelly bars are manufactured according to API-7-1 Spec.

Learn More Petroleum Resources

Buyer’s Guide

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

We can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us your money will be safe.

Get Quick Response

Lake Petro is located in Dongying City, which is famous for Shengli Oilfield and the largest manufacturing hub of petroleum equipment in China. Following the principle of “quality first, science and technology innovated, people oriented”, every Lake Petro person is sparing no effort to provide the customers with best products and services. Our products are based on advanced production line and testing equipment, our products are designed and manufactured according to certification of API, ISO, GOST, etc.