Bucking Unit

- High automatic level.

- Large torque of screwing on/screwing out.

- Wide diameter range for tubing fittings.

- Without slippage or biting the working surface.

- Quick-tightening screw thread; Provide push-pull foce for work piece.

- Torque & pressure information digital display system can be choosen.

- Technical Specification

- Contact Us

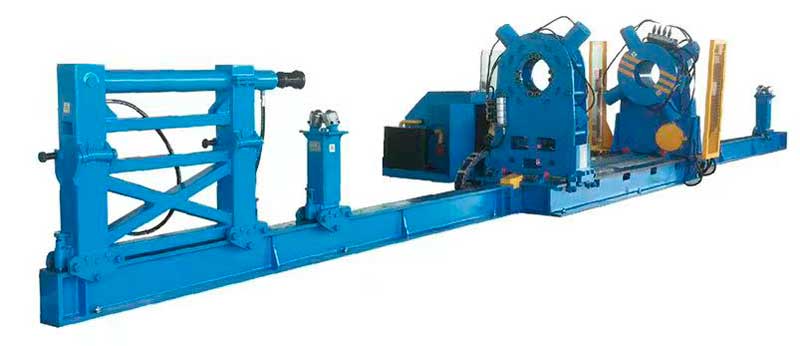

Bucking Unit

Also called Makeup and Breakout Machine

Bucking Unit or Hydraulic Breakout Machine is an important tool used for disassembling/assembling, maintaining of all kinds of drill tools, pipe strings and thread connections for all kinds of downhole equipment. Lake Petro fully rotation torque Bucking Unit is designed for fast and accurate makeup and breakout of premium and non-premium thread tubular equipment. The machine can handle up to a maximum torque of 190,000 ft-lb tracking thread. The Bucking Unit is well suited for repair shops, completion services, offline stand building, and small pipe-thread facilities.

Features and Benefits

- Hydraulically controlled clamp cylinders increase reliability; None Marking damage can be realized.

- Fully rotational with a traversing tail stock.

- More easier for pressure adjustable.

- Accurate graph reports on threaded makeups for full authentication and traceability.

Main Technical Parameters

| Model | LK 7 5/8-25 | LK 9 5/8-40 | LK 10-70 | LK 13 3/8-70 |

| Gripping Range | 2 3/8″ – 7 5/8″ | 2 3/8″ – 9 5/8″ | 2 3/8″ – 10″ | 2 3/8″ – 13 3/8″ |

| Torque Range | 0-25KN.m | 0-40KN.m | 0-70KN.m | 0-70KN.m |

| Rotary Speed | 0-16rpm | 0-16rpm | 0-17rpm | 0-10rpm |

| Hyd Oil Capacity | 80-120L/min | 80-121L/min | 80-122L/min | 80-123L/min |

| System Pressure | 16Mpa | 17Mpa | 18Mpa | 19Mpa |

| Overall Dia(mm) | 2500x1200x1600 | 4500x1200x1600 | 4500x1300x1600 | 4500x1400x1600 |

| Weight(approx.) | 5000KG | 6500KG | 7500KG | 9000KG |

| Model | LK 20-70 | LK 18-160 | LK 18-210 | LK 18-250 |

| Gripping Range | 2 3/8″ – 20″ | 2 3/8″ – 18″ | 2 3/8″ – 18″ | 2 3/8″ – 18″ |

| Torque Range | 0-70KN.m | 0-160KN.m | 0-210KN.m | 0-250KN.m |

| Rotary Speed | 0-10rpm | 0-11rpm | 0-4rpm | 0-4rpm |

| Hyd Oil Capacity | 80-120L/min | 120-160L/min | 160-240L/min | 160-240L/min |

| System Pressure | 16Mpa | 16Mpa | 16Mpa | 16Mpa |

| Overall Dia(mm) | 4500x1400x1600 | 6500x1400x1600 | 6500x2200x2200 | 6500x2200x2200 |

| Weight(approx.) | 10500KG | 12500KG | 18500KG | 22500KG |

The Machine Consists with

- Fixed Hadstock/Traversing Tailstock

- Hydraulic Power Unit

- Torque Control Console

- Hoses Cover

Torque Control System Interface

Optional Accessories

- Extension Beam

- Hyd Support Stand

- Eccentric device

- None marking damage die

- Tailstock top open

- Push/Pull System

Learn More When Inquiring

Buyer’s Guide

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

We can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us your money will be safe.

Get Quick Response

Lake Petro is located in Dongying City, which is famous for Shengli Oilfield and the largest manufacturing hub of petroleum equipment in China. Following the principle of “quality first, science and technology innovated, people oriented”, every Lake Petro person is sparing no effort to provide the customers with best products and services. Our products are based on advanced production line and testing equipment, our products are designed and manufactured according to certification of API, ISO, GOST, etc.